In section 6, one of the yarns used in the samples was bought paper yarn. As the design source for this module was a tree, I wanted to explore the possibility of making my own paper yarn from papers which would otherwise be recycled.

This YouTube video looked straightforward:

http://www.youtube.com/watch?v=jKAnC1cW6zA

Cutting half inch strips from The Saturday Telegraph I started to spin the strips using a spinning wheel, with no success. A very knobbly yarn formed that wouldn’t wind onto the bobbin and kept breaking (Image 30). Perhaps this was because I was using a wheel and not a spindle, as in the video, as the wheel puts more pressure on the yarn being spun. Note the bursts of colour in the yarn – Gardening Section=bursts of colour: Financial Section=black and white.

Not put off I found the following blog:

http://mademoisellechaos.blogspot.co.uk/2010/04/how-to-make-yarn-or-seed-tape-from-old.html

Moisture, it seems, was the key to success. Image 31 shows the spun yarn winding on to the bobbin. Very exciting.

After spinning strips from The Telegraph, I tried white tissue paper and the brown paper used by Amazon for packing, both successfully.

The tissue when moist was very delicate and had to be handled with great care or it just ripped before it could be spun. Perhaps it was too moist. Once spun it became stronger.

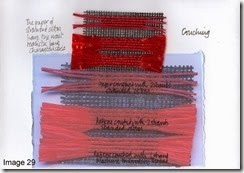

All three yarn samples, The Telegraph, tissue and brown paper were then painted with Koh-i-noor watercolours. All yarns took the paint well.

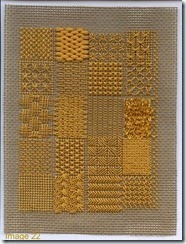

I then sampled how the yarns handled in an attempt to produce a raised darning stitch. When using the newspaper yarn and a canvas gauge of 12 holes to the inch, due to my lap looking as though it was snowing almost as soon as I started sewing it was obvious early on that it shredded easily. The yarn spontaneously broke as I pulled it through the canvas soon after. It was breaking by the needle as though the friction of being pulled through the canvas at this point was too great. I persevered and produced a small warp through which I wove a tissue yarn weft.

The tissue yarn was much more forgiving and so in my second sample I used it as the warp and the newspaper yarn as the weft, so putting it under less pressure.

In an attempt to make the newspaper yarn more robust I treated it with:

- acrylic wax – made the yarn less flexible and it still broke easily

- olive oil – darken the yarn, irreversibly it would appear, also made it swell and very fragile

- beeswax – ran the yarn through a block of beeswax, as in goldwork/patchwork. Made yarn easier to sew but still fragile.

- PVA – strengthened the yarn. Best result.

Ideas to try with newspaper yarn:

- canvas with larger holes so less friction

- larger eyed needle so less pressure on thread at this point

- spin narrower strips

- tear the ends of the strips at an angle before spinning so less bulk at join.

To be continued…